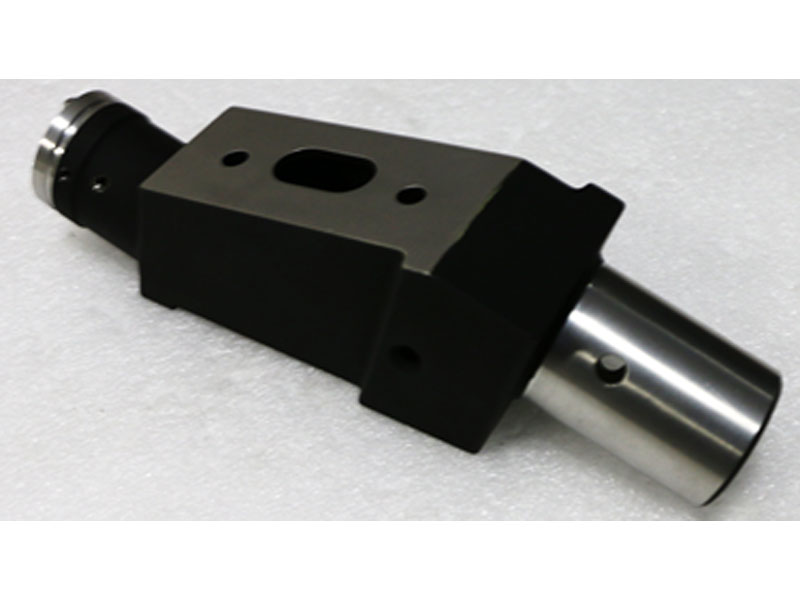

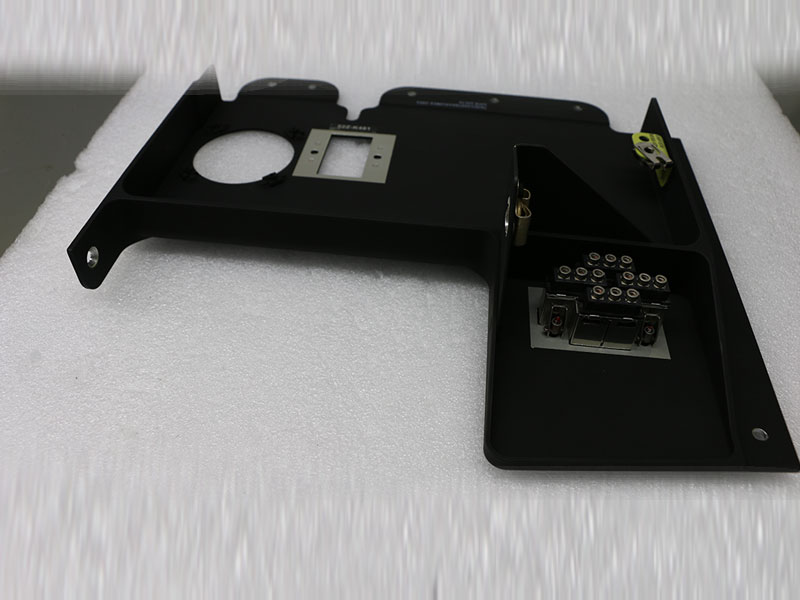

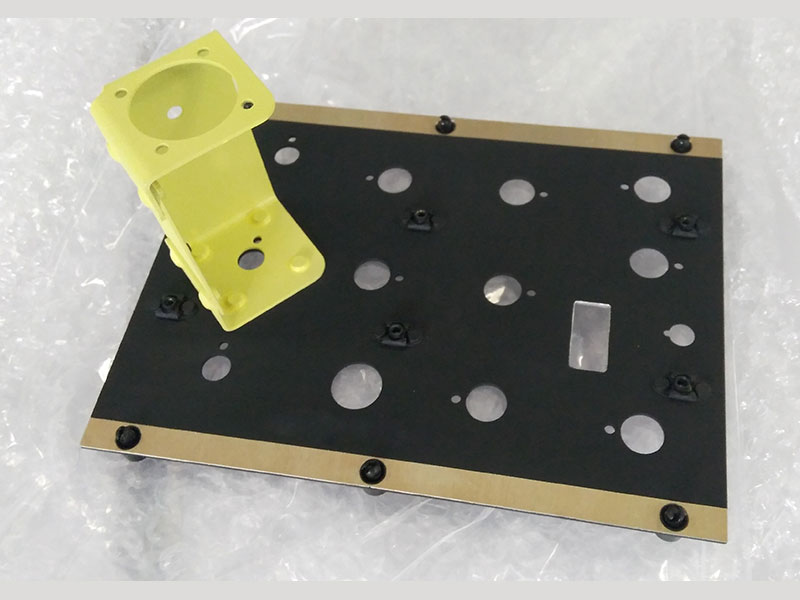

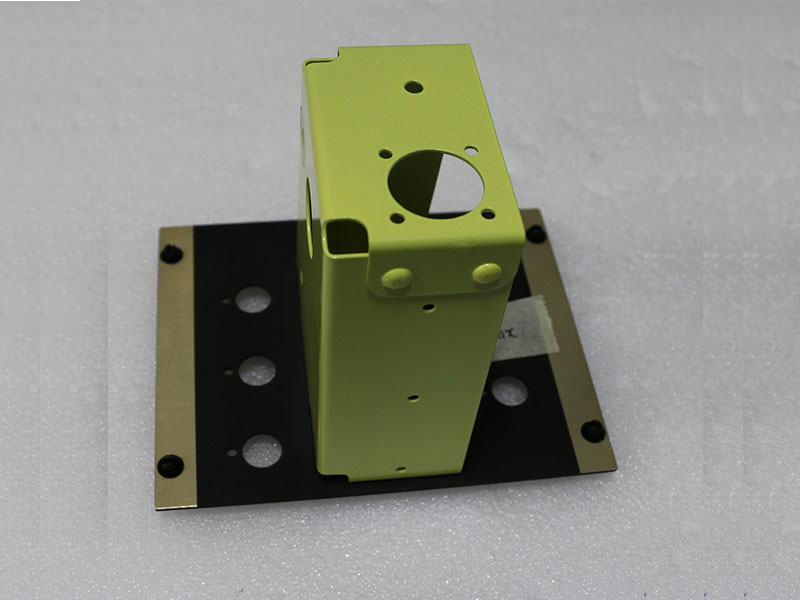

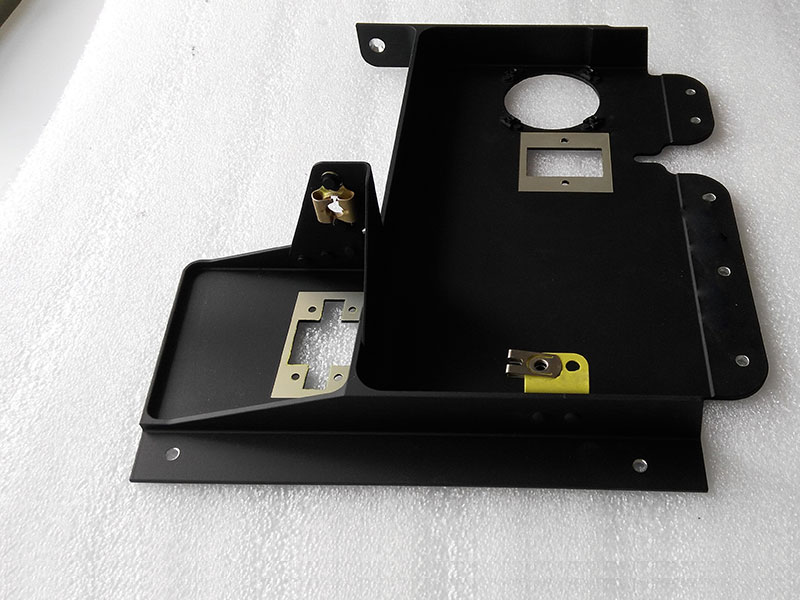

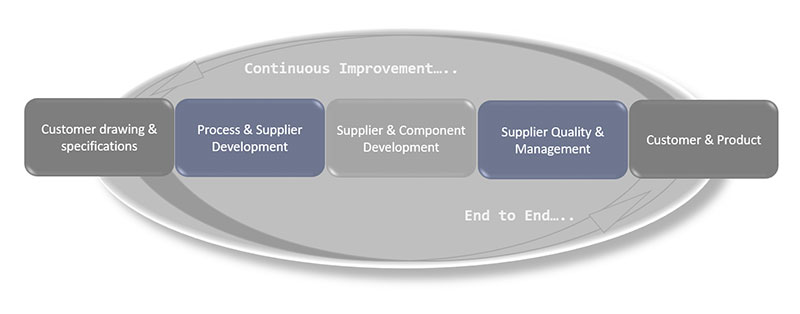

Glodesi combines its product with its program management skills with close tolerance fabrication, precision machining, complex assembly &integration, heat treatment, chemical processing and paint capabilities to create superior one-stop shopping value for our customers. This capability combined with an ingrained Lean Manufacturing and Continuous Improvement culture, yields tremendous value for higher level assembly and integration solutions. Our strategic partners are NADCAP approved for the following surface treatment processes.

Raw materials mostly used are Al 7075, Al 6061, Al5052, Al 2024 etc., of customer specified temper conditions. Austentic ,Matensitic, PH and Duplex types of steels (SS 303, SS 304L, etc), Copper Beryllium alloys of both commercial and aerospace MIL grades procured from the customer approved suppliers from different parts of the world meeting aerospace & defense standards.

Click here to submit a request for Company Portfolio

Skora Tech Park, Plot No. 71 Off EPIP Industrial Area Survey No. 151 Hoodi Village, Hobli,

Krishnarajapura, Bengaluru, Karnataka 560066

Copyright © 2022 GloDesi Technologies (P) Limited. All rights reserved.